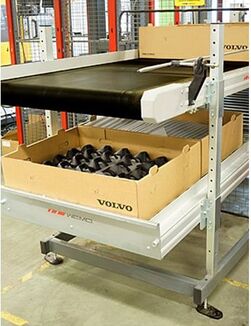

Box Handling Systems

Boxes in plastic or cardboard can be fed and stored fully automatically in concepts for saving man power and floorspace.

This system is easy to integrate for existing as well as in new robot automation cells.

• Buffering and stacking of components

• Handling of large or small boxes

• Handling of pallets or fixtures

• Simple installation and start-up thanks to integrated controllers

|

|